Cargo Scanner

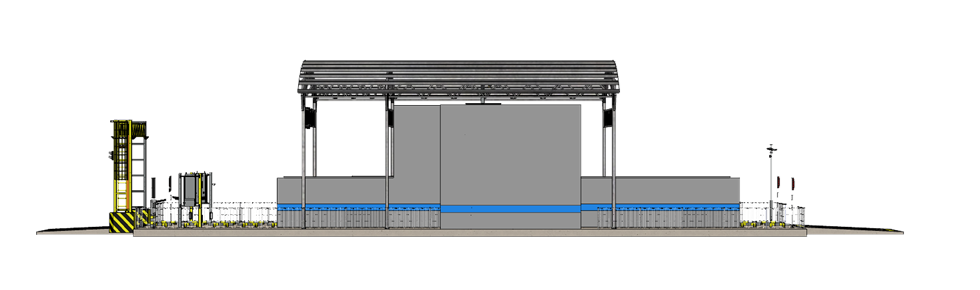

CIS-M4 Multi Backscatter Inspection System

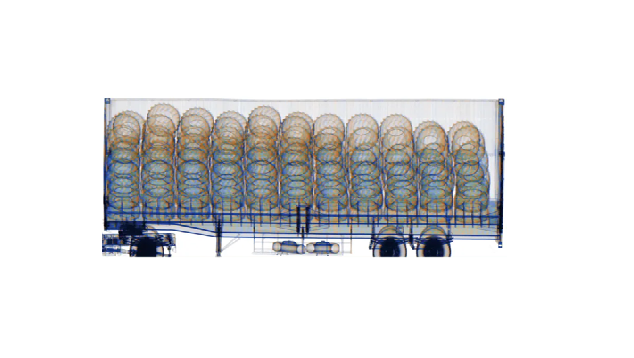

Explore the CIS-M4, an advanced cargo and vehicle inspection solution by ZTRON PTE. LTD. Utilizing high-energy transmission and backscatter technology, it offers comprehensive multi-view imaging for thorough security checks. Designed for efficient 100% screening at seaports and borders, its AI-powered analysis ensures precision in detecting high-density cargo with penetration up to 350mm, ideal for high-security environments.

Discover the CIS-M4 Advantages

An overview of CIS-M4’s essential capabilities.

Multi-View Imaging

Provides top, side, and backscatter images for thorough inspection.

AI-Powered Analysis

Utilizes artificial intelligence to ensure efficient cargo screening.

High Penetration Depth

Capable of scanning through dense cargo up to 350mm thick.

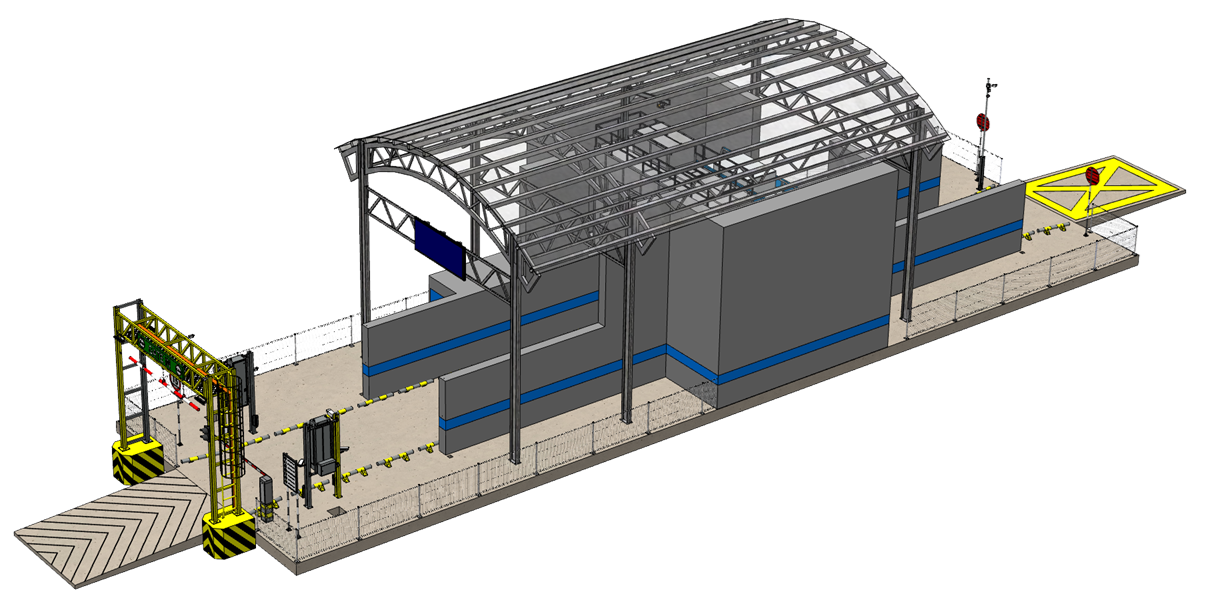

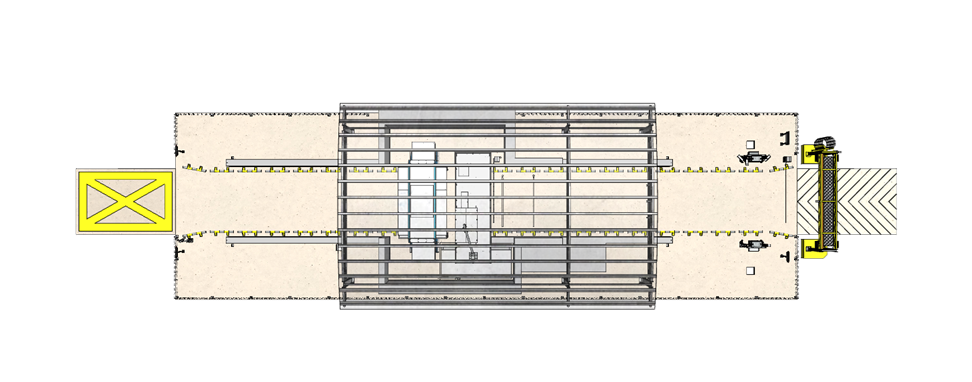

Seamless Integration

Designed for easy installation at seaports and border checkpoints.

Advanced Inspection Technology for Secure Cargo Screening

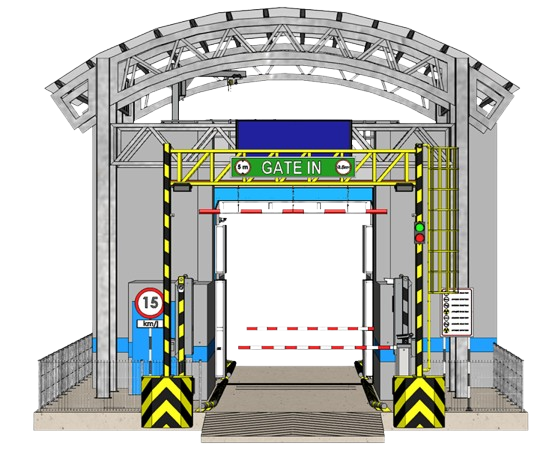

Multi-View Drive-Through Portal

Utilizes high-energy transmission and backscatter imaging for comprehensive vehicle and cargo analysis.

AI-Powered 100% Screening

Ensures efficient inspection at seaports and borders with intelligent automation and rapid processing.

High Penetration Depth & Imaging Precision

Delivers detailed top, side, and multiple angle images for thorough cargo evaluation and threat detection.

12 ADVANTAGES

Power By AI

Identify Liquid tank, Gas Tank, Liqueur, etc.

Safe To Scan

Safe to scan via drive – through

Low Radiation Dose

Absorbed dose per scan as low as 0.1 μSv/scan

Instant X-Ray Image

Faster results, enhanced image quality

Customizable

Able to customize according to user’s requirements

Digital Storage and Sharing

Seamless communication and collaboration among officers

High Throughput

Up to 150 standard 40’ ISO cargo containers per hour

Real Time Material Discrimination

Metal | Heavy Metal | Organic | Inorganic

High Image Quality

Grayscale, BnW, pseudocolor & Colour images

Self-Diagnostic System

Determine the X-ray efficiency

Fully Automated Operation

Fully automated scanning system which requires no manual operation

High Steel Penetration

Can penetrate up to 350mm thick steel

| General Specification |

| Type of Non-Intrusive Inspection System |

| Type of X-Ray Accelerator |

| Operation Mode |

| Scanning Speed |

| Inspection Throughput |

| Vehicle Transit Speed |

| System Warm Up Time |

| Footprint [W x L x H] |

| Tunnel Dimension [H x W] |

| Max. Height of Scanning |

| Min. Height of Scanning |

| Nominal Energy (MeV) |

| Steel Penetration |

| Description |

| Fixed portal type |

| Side and diagonal view of dual energy Betatron (upgradable to 4 energy) |

| Vehicle drive-through with full scan mode or cabin mode |

| Less than 20 seconds per scan |

| Average inspection throughput rate more than 150 standard 40’ ISO cargo containers per hour |

| 5-15 km/hr(optional), can reach up to 30 km/hr |

| Less than 5 Minutes |

| 10m x 40m x 10m (Customizable) |

| 5m x 4.4m (Customizable) |

| approx. 5.2m above ground (Customizable) |

| approx. 0.35m above ground |

| 7.5/4 MeV, Pulsed Radiator (400 Hz) |

| Top View Steel (320mm) Side View Steel (350mm) |

* Comply to ANSI N42.46-2008 and IEC62523

| Features |

| Spatial Resolution |

| Contrast Sensitivity |

| Wire Detectability |

| Pseudo Color |

| Zoom |

| Measurement Length/Area |

| Edge Enhancement |

| Metal Discrimination |

| X-Ray Detector |

| Description |

| 4mm vertical, 3mm horizontal |

| 1% behind 100mm steel 2% behind 150mm steel 2% behind 200mm steel |

| 1.3mm wire in air |

| Yes, at least 4 colors |

| At least 16x Zoom |

| Yes |

| Yes |

| Yes (Organic, Inorganic, Metals and Heavy Metals) |

| Dual Row Dual energy |

| FEATURES |

| Absorbed Dose Per Scan |

| Operator Absorbed Dose Rate |

| Radiation Safety Indicators |

| DESCRIPTION |

| <=0.1 μSv (Speed:5km/h)* |

| <=0.5 μSv/h |

| Complies with international IEC 62463-2010 and US ANSI N43.17-2009 standards |

| FEATURES |

| X-Ray Source |

| Alignment |

| Scanning Height |

| Throughput Rate |

| Perfect Scanning Distance |

| Scanning Speed |

| Steel Penetration |

| DESCRIPTION |

| 225keV Metal ceramic X-Ray tube |

| Flying Point Device |

| 3.6m |

| 200 units of 17m container vehicles per hour |

| 1.5m |

| 0.5~10km/h |

| Up to 7mm |